LINK devotes to providing “turn-key solutions for LPG cylinder production plant”, namely design and research- complete equipment manufacturing and procurement-commissioning and delivery – management and operation”. LINK has a complete raw material supply chain and equipment supply chain, and can learn the market price at the first time, and purchase equipment and materials at the most affordable price in the optimal time period.

We have a number of cooperative equipment factories, and we continue to maintain stable orders. There are thousands of equipment types and functions, which can ensure the normal operation of various productions. And there are various raw material suppliers, such as steel, parts, pigments, etc.

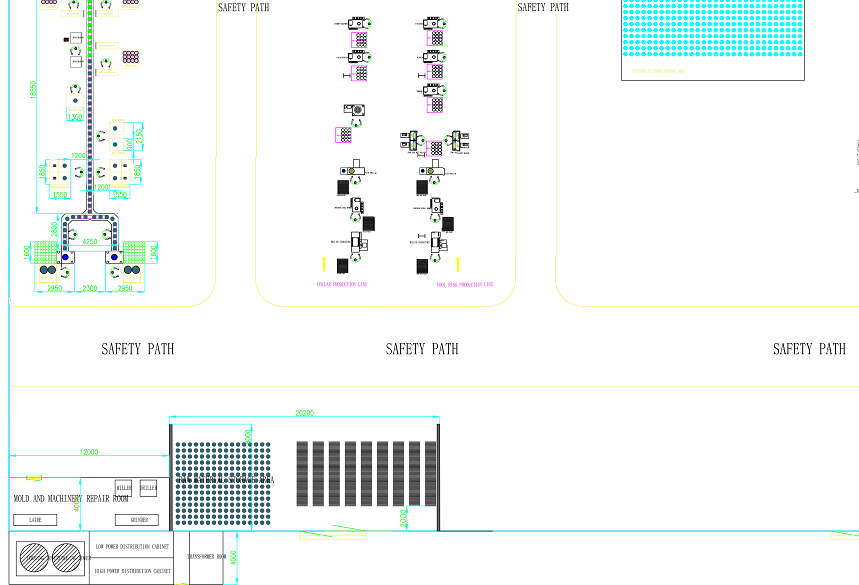

The cooperation case in Kenya adopts the form of EPC+M+O one-stop service to improve the equipment matching rate, operation rate, economic and technical indicators of production, shorten the construction period and enhance benefits. The Kenya factory has a large scale, covering an area of 16,000 square meters and a large number of personnel. It has reached a new high annual output: 2 cylinder production lines, each of which has an average annual output of 300,000 pieces.

The cooperation case in Nigeria introduces EPC+M+O one-stop service for the first time. The factory is fully entrusted to our company for operation and management, and our company provides technology, equipment, materials, operation and management services, so as to achieve win-win cooperation. Today, the Nigerian factory covers an area of more than 5,000 square meters, with an average annual output of about 400,000 units.