Liquefied petroleum gas (LPG) cylinders are one of the main equipment for storing and transporting LPG. In order to ensure its safety performance, the industrial sector usually conducts mechanical performance tests on LPG cylinders. So, how is the LPG cylinder tested for mechanical properties?

The mechanical performance test of LPG steel cylinder is to evaluate the compression resistance, bending resistance and twisting performance of the steel cylinder through a series of tests. The testing is divided into three phases: raw material testing, manufacturing process testing and in-use testing. In the following, we describe these three phases of testing in detail.

Raw material testing

First, raw materials need to be tested to ensure they meet relevant standards. These tests include the detection of the chemical composition, hardness and tensile strength of the steel plate blank, as well as the conformity test of the mechanical properties and dimensions of the material. Among them, the hardness test usually uses a Brinell hardness tester, and the tensile strength test uses a tensile testing machine.

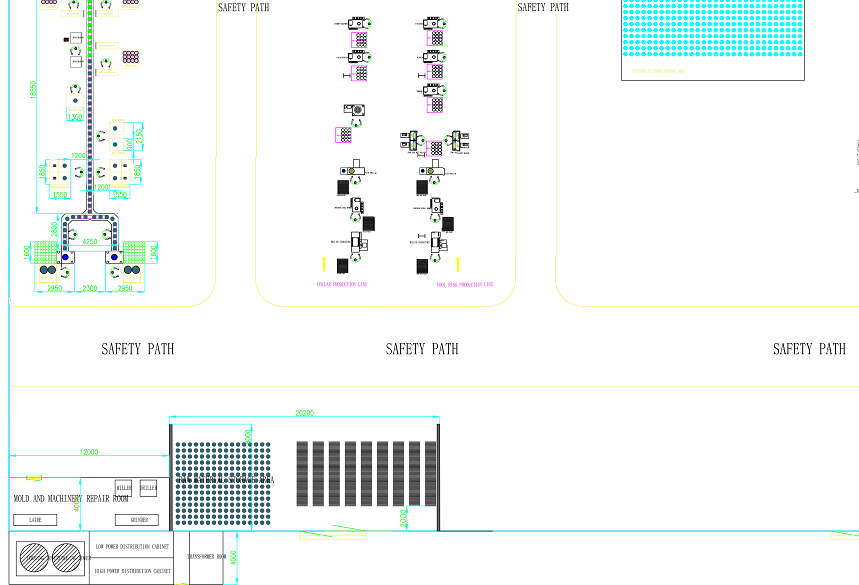

Manufacturing Process Testing

The manufacturing process of LPG cylinders requires continuous control and inspection. After the steel plate is formed, a series of processes such as welding, finishing and painting are required, and strict quality control is carried out for each process. Therefore, it is necessary to test the mechanical properties of the welding seam, polishing and coating to ensure the flatness and overall performance of the steel cylinder. The goal of this process is to ensure that the cylinders are manufactured without any material flaws and construction flaws to increase their safety.

Test in use

After cylinders are put into service, an in-service test is carried out. These tests include those for capacity, density, mass, dimensional deformation, yield point and strength. The specific operation is to use wear-resistant, corrosion-resistant and high-pressure gas test instruments to perform mechanical performance tests. This can also help detect any damage, deformation or cracks in the cylinder to avoid sudden explosions under high pressure. At the same time, it can also monitor the quality of steel cylinders and find quality problems in time.

In short, the mechanical performance test of LPG liquefied petroleum gas cylinders is very important. These tests ensure that cylinders are strong, of the right material and of a robust structural design to keep users safe.