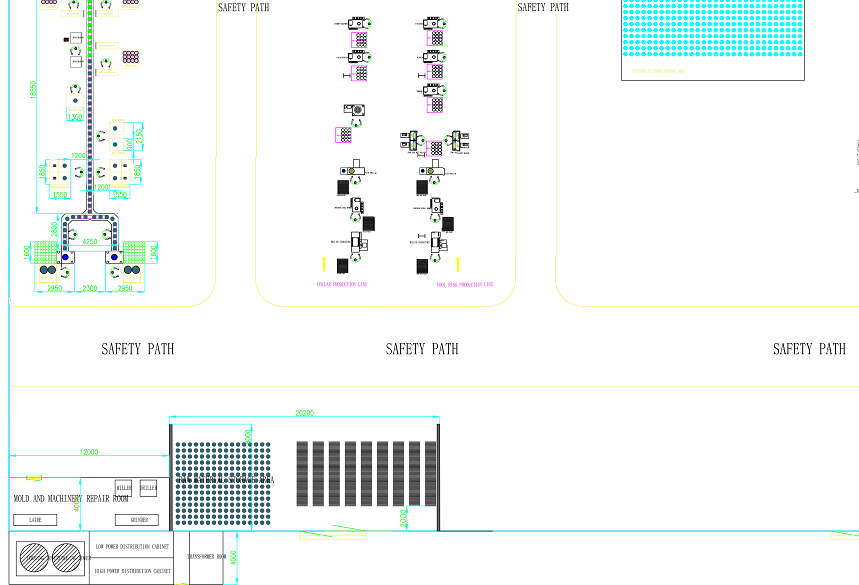

Liquefied petroleum gas (LPG) cylinder is a special container used to store liquefied petroleum gas, which has the characteristics of high pressure and corrosion resistance. In the production process of LPG cylinders, the hydraulic press is one of the important process equipment. The hydraulic press realizes the pressing and shaping of metal materials through the transmission of liquid media, and controls the hydraulic system, electrical system and mechanical system through the control system.

Hydraulic press machine plays a vital role in the production process of LPG cylinders.

First, the hydraulic press exerts a certain amount of pressure through the movement of the hydraulic cylinder, so that the metal material enters the mold for stamping and forming. This method can ensure the accuracy and stability of the external dimensions and internal structure of the LPG cylinder.

Secondly, the hydraulic press has a mold opening and closing function. In the production process of LPG cylinders, the hydraulic press controls the opening and closing of the mold through different actions to facilitate placing metal materials into the mold and completing the stamping and forming process operations.

This method can achieve rapid production of LPG cylinders and improve production efficiency.

The operating instructions for the hydraulic press are as follows.

First of all, the operator needs to carefully read the operating manual of the hydraulic press and understand the working principle, operating methods and precautions of the hydraulic press. Before operation, it is necessary to check whether all components of the hydraulic machine are intact and ensure that the hydraulic system and electrical system of the hydraulic machine are operating normally.

Operators need to wear protective equipment that meets safety standards and ensure the safety and cleanliness of the operating area. Before operation, the metal materials and molds need to be prepared, and the molds must be installed and adjusted correctly.

Next, the operator needs to turn on the power of the hydraulic press and pressurize the hydraulic system of the hydraulic press to the set working pressure. During the pressurization process, you need to pay attention to the indicator of the hydraulic machine to ensure that the hydraulic system is working properly.

When the hydraulic system reaches the set working pressure, the operator can place the metal material into the mold and complete the pressing and forming process operations by operating the switch or foot pedal on the hydraulic press. During the operation, you need to pay attention to the operation of the hydraulic press, and adjust and control the operation of the hydraulic press as needed.

After completing the pressing and forming process operations, it is necessary to turn off the power of the hydraulic press and release the pressure from the hydraulic system of the hydraulic press. At the same time, the metal materials and molds need to be removed, cleaned and maintained.

In short, the hydraulic press plays an important role in pressing and opening and closing molds in the production process of LPG cylinders. When operating a hydraulic press, operators need to carefully follow the requirements of the operating manual and pay attention to safety and details during the operation to ensure the production efficiency and product quality of LPG cylinders.